What Discovery Revealed for Meridian Equipment

Synthesized example from real engagements. See the methodology, findings, and recommendations you'll receive.

Each Discovery is unique. The patterns below are drawn from actual client work. Names changed. Insights real.

Meet Meridian Equipment

A regional distributor with 25 employees. Their primary system is an industry-specific ERP that handles inventory, orders, and basic accounting.

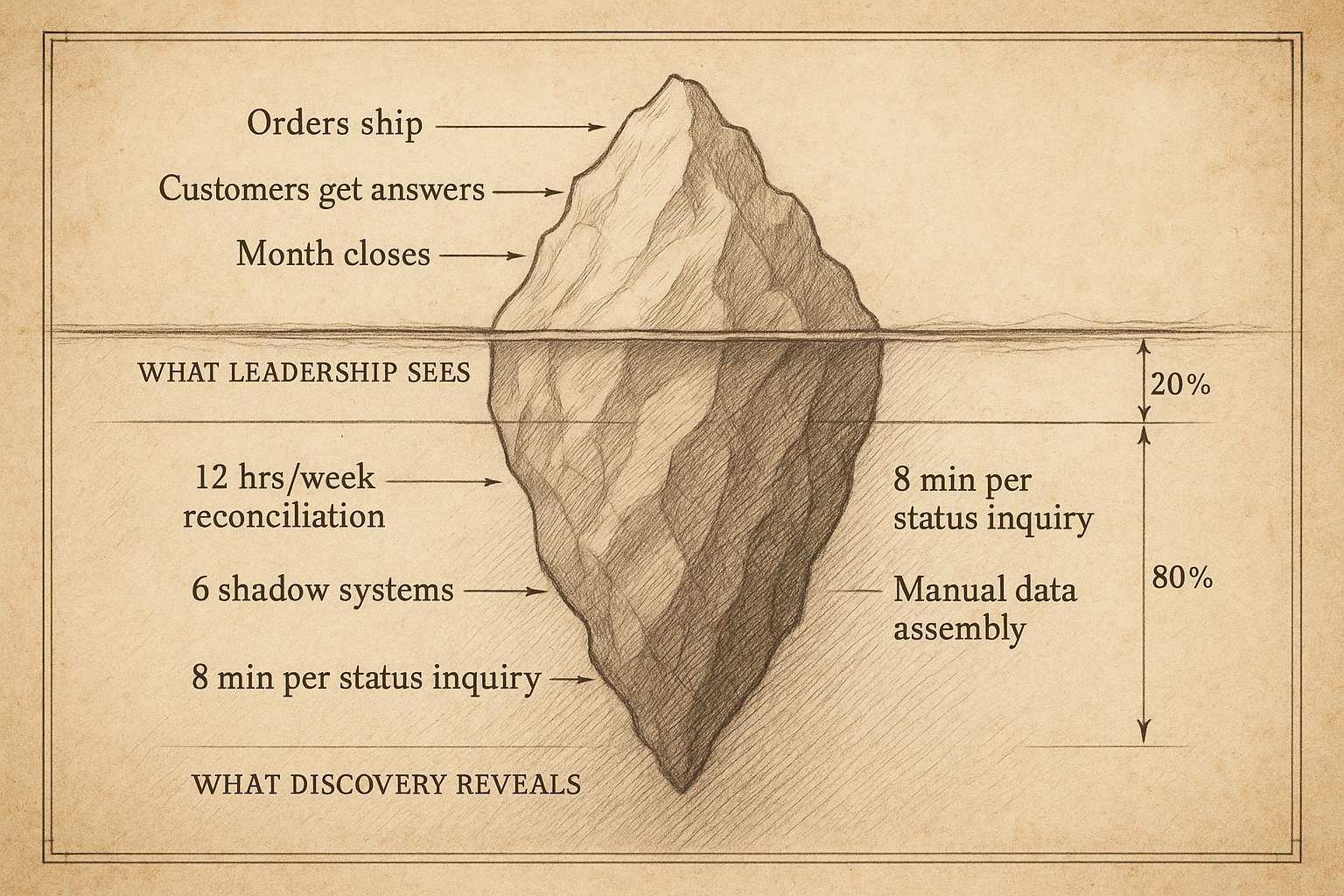

From the outside, things worked. Orders shipped. Customers got answers. Month closed.

From the inside? Different story.

The Hidden Cost of "Good Enough"

Five interviews. Four pain points. Quantified impact.

Staff check the ERP, then the shared spreadsheet, then ask a colleague, then maybe check text messages. Meanwhile, the customer waits.

What this actually costs:

- • 30 inquiries/day × 8 min = 4 hours daily just answering "where's my order?"

- • At $25/hr, that's $25,000/year in labor on a task that should take seconds

- • Customers perceive slow response as disorganization, eroding trust

- • Staff frustration compounds as they repeat the same hunt dozens of times daily

Every week, someone spends a day and a half comparing spreadsheets to the ERP, hunting for discrepancies, fixing mismatches by hand.

What this actually costs:

- • 624 hours/year, nearly a third of one full-time employee

- • At $30/hr, that's $18,700/year in pure waste

- • Month-end becomes a crunch, errors slip through under pressure

- • That person could be serving customers, improving processes, or going home on time

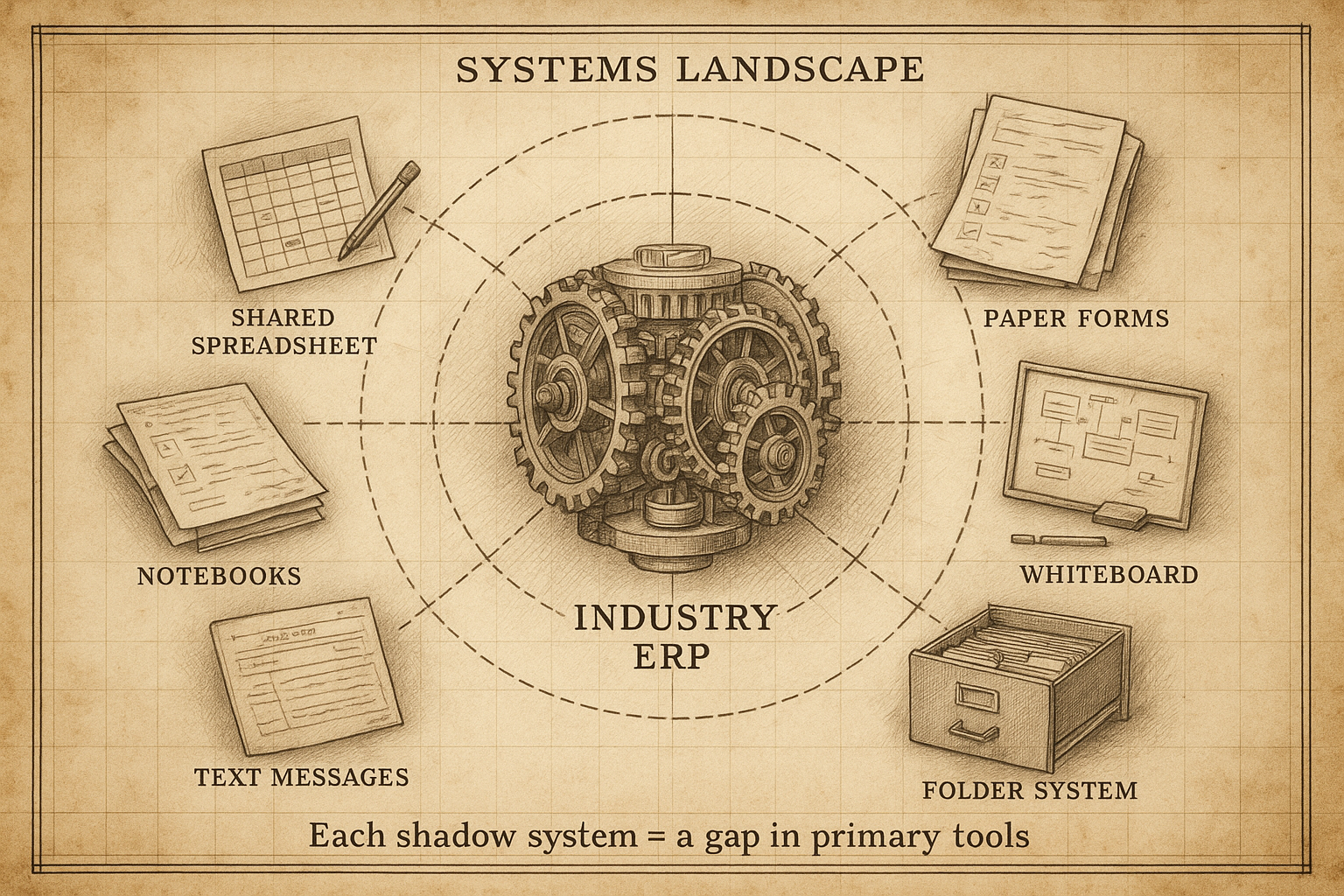

Spreadsheets, paper forms, notebooks, whiteboards, text threads, folder systems. Each one exists because the official tools have gaps.

What this actually costs:

- • Every new hire learns 6 unofficial systems on top of the ERP

- • "Which spreadsheet is current?" becomes a daily question

- • When the person who maintains the whiteboard is out, priorities become unclear

- • Data lives in silos, decisions get made on incomplete information

Customer calls, info goes in the ERP. Then the spreadsheet. Then the paper form. Then maybe a text to the warehouse. Same data, four times.

What this actually costs:

- • 50 orders/day × 4 entries × 2 min = 6+ hours daily in redundant work

- • Each entry is an error opportunity: typos, transposed numbers, missed updates

- • When systems disagree, someone has to figure out which one is right

- • Staff know it's wasteful but have no alternative

Discovery translates daily frustrations into annual cost, shows how inefficiencies compound, and reveals what becomes possible when they're addressed.

Curious what Discovery would reveal about YOUR organization?

The same 5-stage process. Applied to your reality.

Schedule Discovery Call →

Shadow Systems Everywhere

Six unofficial tools compensated for what the ERP could not do:

- • Shared spreadsheet tracking orders the ERP cannot surface

- • Paper forms for equipment inspections

- • Personal notebooks for customer preferences

- • Whiteboard for daily priorities

- • Text messages for urgent coordination

- • Folder system for warranty documents

Shadow systems are not failures. They are adaptations. They show where official tools do not match actual work. Discovery makes these visible so you can decide what to do about them.

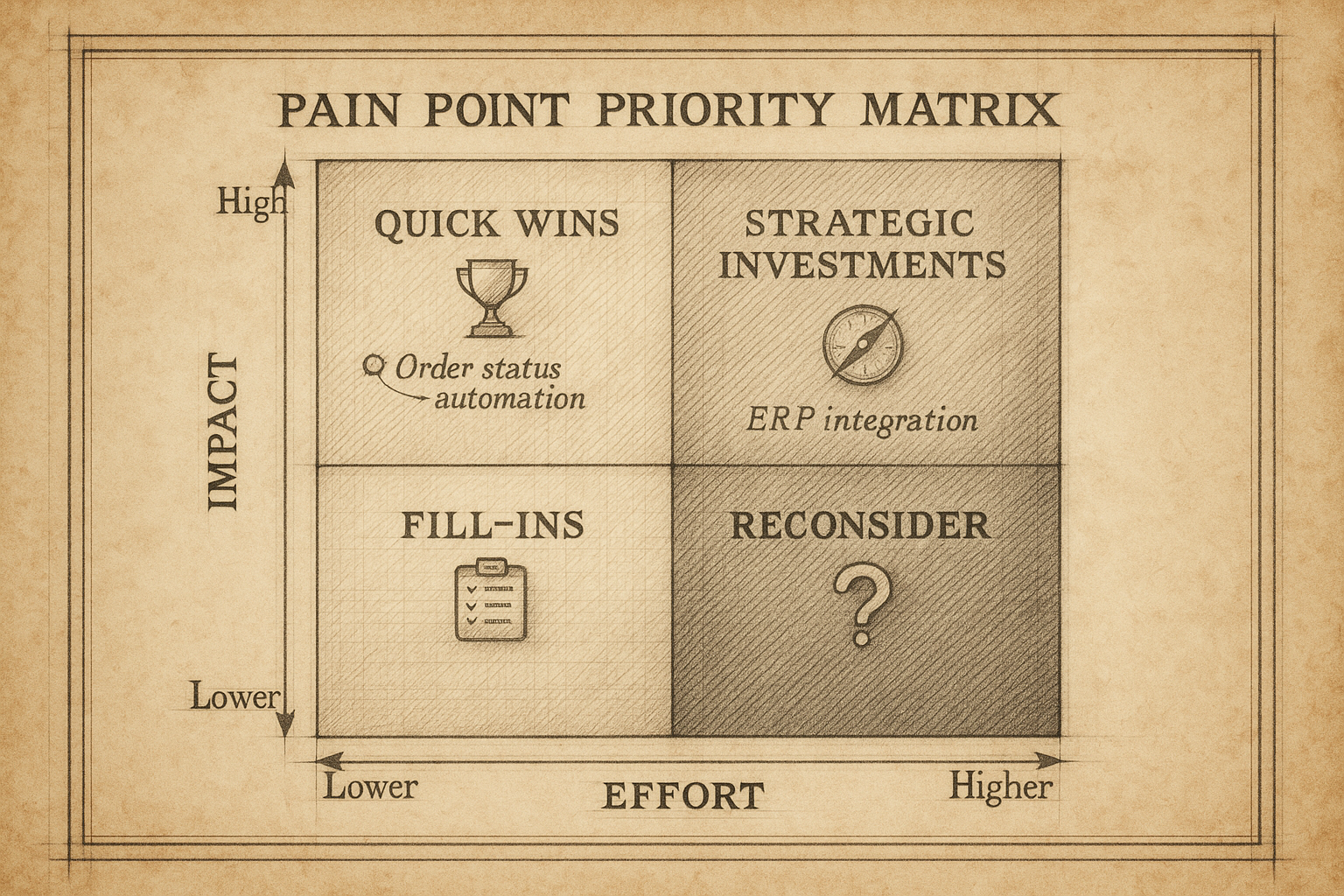

From Diagnosis to Action

Quick Wins (High Impact, Lower Effort)

- • Automate order status lookups. Currently 8 minutes per inquiry.

- • Create single source for daily priorities. Replace whiteboard plus text message coordination.

Strategic Investments (High Impact, Higher Effort)

- • Integrate inventory counts with ERP

- • Build customer communication history into accessible format

Fill-ins (Lower Impact, Lower Effort)

- • Standardize equipment inspection forms

- • Create vendor portal credential management

Phased Recommendations

Discovery does not prescribe. It illuminates. Your organization decides what happens next.

Phase 1: Quick Wins

4-6 weeks

Address order status lookup and daily priority coordination. Demonstrate value immediately while building momentum.

Phase 2: Infrastructure

Requires deeper assessment

Inventory integration and customer communication history. May involve system changes.

Phase 3: Strategic

Longer-term

Evaluate ERP utilization. Determine whether current system can serve needs or requires augmentation.

This Discovery examined operations and customer service workflows. Future phases could explore financial processes, IT infrastructure, or vendor relationships.

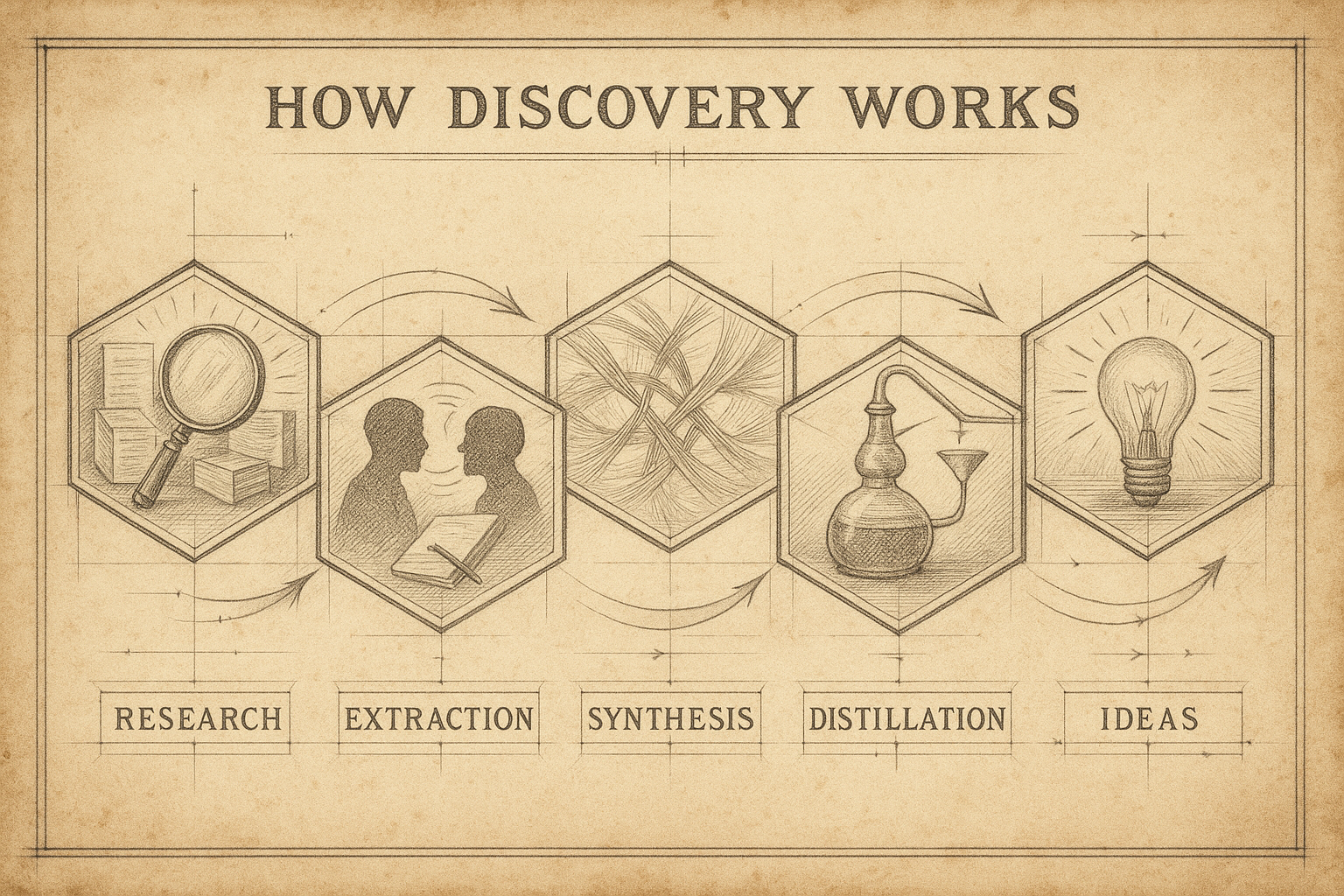

How Discovery Works

The 5-stage process that surfaced these findings

1. Research

Gather context before talking to anyone.

2. Extraction

Surface how work actually flows.

3. Synthesis

Identify patterns across interviews.

4. Distillation

Prioritize by impact and effort.

5. Ideas

Specific opportunities, not generic advice.

How We Validate Findings

Findings gain confidence when multiple people describe the same issue independently.

Strong Corroboration (4/5)

- • Order status requires multiple sources

- • Customer calls interrupt focused work

- • Month-end reconciliation crunch

Moderate (2-3/5)

- • Inventory counts don't match ERP

- • Training takes longer than expected

- • Reports require manual assembly

Isolated (1/5)

- • Vendor portal login issues

- • Specific customer preference

Your Hidden Costs Are Different. The Methodology Isn't.

Your organization is not Meridian Equipment. Your systems, people, and challenges are your own.

But the process that surfaced $43,700 in annual waste from just four pain points? That works across industries and contexts.

Schedule Discovery Call

60-minute conversation → Clarity Document within 48 hours → Actionable insights you keep forever.

Whether we work together or not, the findings are yours.

This example synthesizes patterns from multiple real engagements. Actual Discovery reports reflect the unique context of each client.